BMW Group Celebrates Opening the World's First Virtual Factory.

Automaker brings power of industrial AI to its entire production network as part of its digital transformation.

Moving from concept to market faster than your competitors is one of the hallmarks of a successful, sustainable product development strategy.

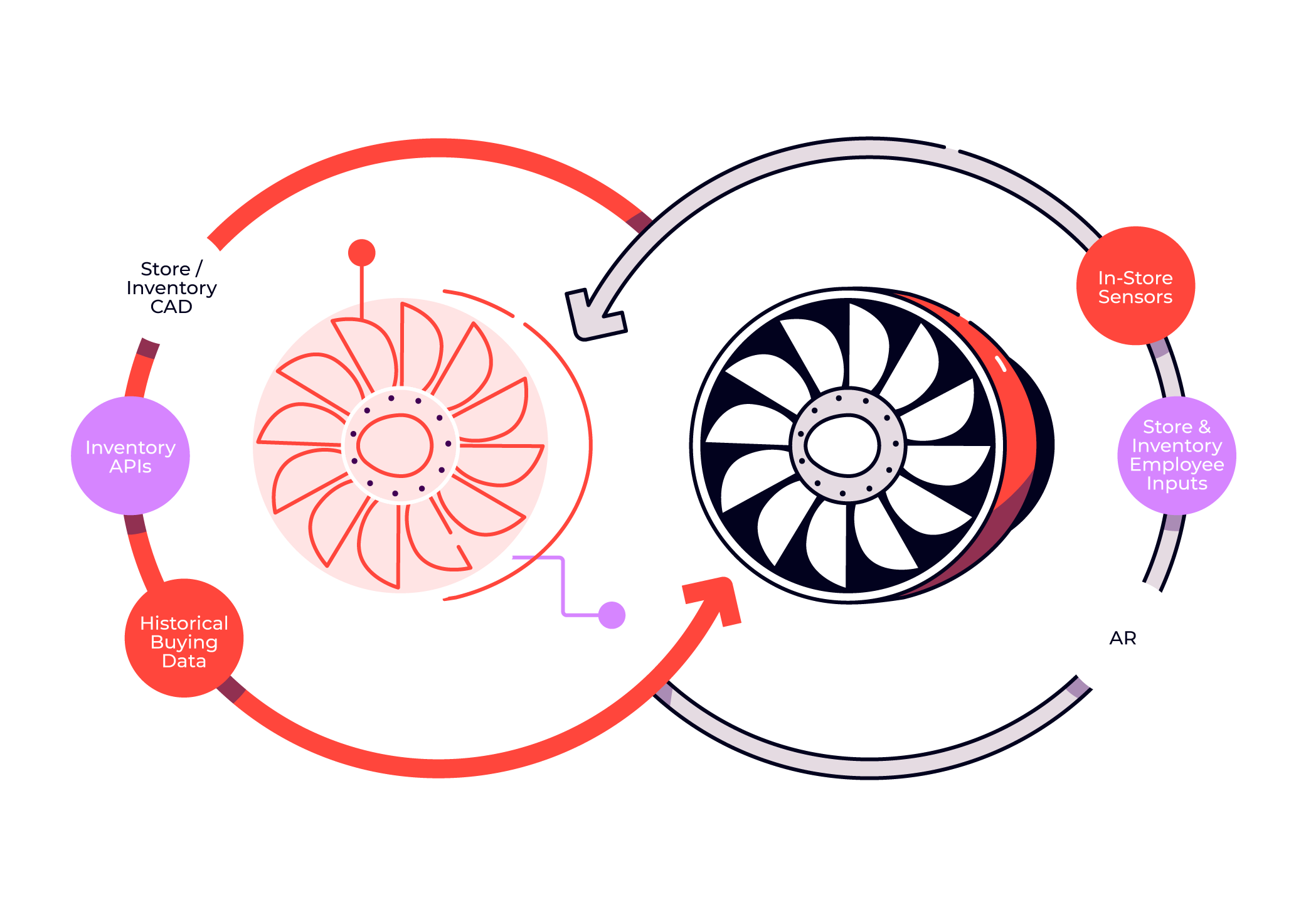

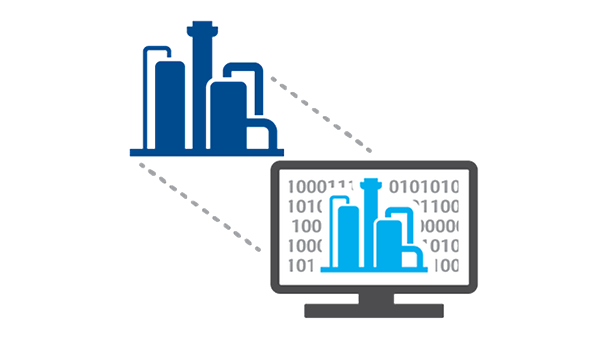

Digital twins are proving to have an oversized impact on businesses using them to curate data from multiple sources and activate it to improve outcomes at every step through design, manufacturing, and support.

Digital twins provide a dynamic, virtual replica of physical assets or systems, enabling real-time monitoring, simulation, and optimization.

IoT sensors generate big data in real time that is analyzed in real-time to identify problems. This ability enables businesses to effectively predict maintenance, improving production line efficiency and lowering maintenance costs.

It’s difficult or even impossible to get a real-time, in-depth view of large systems. However, a twin can be accessed anywhere, enabling users to monitor and control the system performance remotely.

The availability of a large amount of real-time data and advanced analytics enables businesses to make better and faster decisions about whether or not, adjustments to a manufacturing value chain are financially sound.

Process automation and 24/7 access to system information allow technicians to focus more on inter-team collaboration, improving productivity and operational efficiency.

The concept of digital twins, a digital replica of a physical asset, process, or system, is transforming industries worldwide. However, like any new technology, implementing digital twins presents certain challenges for organizations

Automaker brings power of industrial AI to its entire production network as part of its digital transformation.

This demo showcases how real-time 3D collaboration can shorten the time between decision-making, action and feedback.

Accelerated Today, Ready for Tomorrow

Enterprise HPC adjusted to your special needs

Let’s discuss how we can help you